- Home

- |

- Field cases

- |

- Subsea Non-intrusive Flow Tem…

Subsea Non-intrusive Flow Temperature Monitoring on long subsea gas pipeline

ClampOn was tasked with developing a solution for temperature monitoring along a long subsea gas pipeline from a large offshore field

Challenge

ClampOn was tasked with developing a solution for temperature monitoring along a long subsea gas pipeline from a large offshore field. Unlike oil pipelines, gas pipelines are typically uninsulated, making non-intrusive temperature monitoring difficult due to ambient seawater affecting skin temperature.

Intrusive PT (Intrusive pressure and temperature) sensors were only installed at the field and onshore terminal. Two contractors performed thermal simulations with very different results, hence a need for actual measurements.

Approach

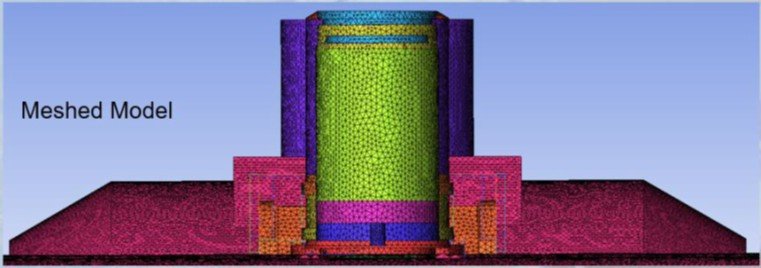

To enable reliable temperature readings, a localized insulated patch was designed. The patch displaces the seawater and allows the temperature to stabilize, enabling accurate measurements. Initial CFD modeling was performed by SWAX engineering to determine the minimum insulation area required, and the time required for stable temperature.

CFD study

Design

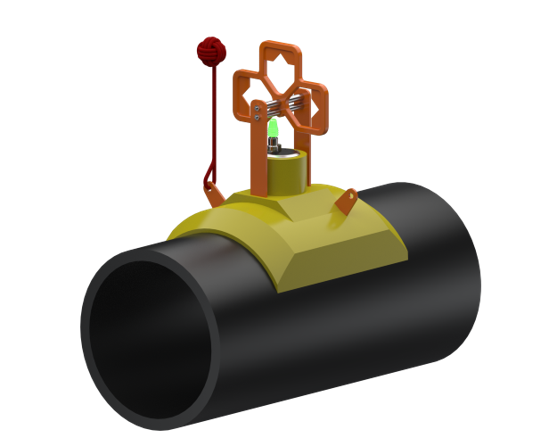

The insulated patch contains permanent magnets for secure attachment to carbon steel pipes. Two instrument versions were developed:

- Standalone unit: Battery-powered, stores data locally, and transmits temperature readings via LED beacon using Morse code for ROV interpretation.

- ROV-integrated unit: Transmits data via serial connection to topside systems.

The temperature sensor is housed in the lower section of the patch, which traps seawater. A specially designed ROV handle with three grip points allows flexible installation angles, including 6 o’clock pipe positions.

Results

The temperature stabilized in under one hour, allowing for timely measurements. Calibration was performed at the field end using the existing PT sensor, and the results showed good correlation. The solution proved effective.

Conclusion

ClampOn’s Subsea Flow Temperature Monitor demonstrated its suitability for gas pipelines, even in non-insulated environments. The solution offers flexibility, reliability, and fast deployment, making it ideal for temporary inspections.

ClampOn Subsea Flow Temperature Monitor

We talked to Kjetil Nysæter from the R&D department at ClampOn - he has been involved in developing the ClampOn Subsea Flow Temperature Monitor

Additional information about the ClampOn Subsea Flow Temperature Monitor

Field cases

-

20.06.25

Installation of Subsea Corrosion-Erosion Monitor (CEM) offshore India

Installation and configuration from vessel to seabed

-

09.12.24

What can we do to prevent choke failure?

Helping the operator by using ClampOn Choke Condition Monitor to avoid producing with a choke at an opening that can cause high vibration or sound pressure levels

-

02.12.24

The Subsea Corrosion-Erosion Monitor installed from Pipe Laying Vessel

The first installation of the Corrosion-Erosion Monitor onboard a pipe-laying vessel and submerged as a fixed part of the pipeline

-

02.12.24

The ClampOn Corrosion-Erosion Monitor used for integrity monitoring of buried pipes

The instrument was installed underground with cabling to a cabinet with solar power and radio telemetry.