By: ClampOn AS

Published:

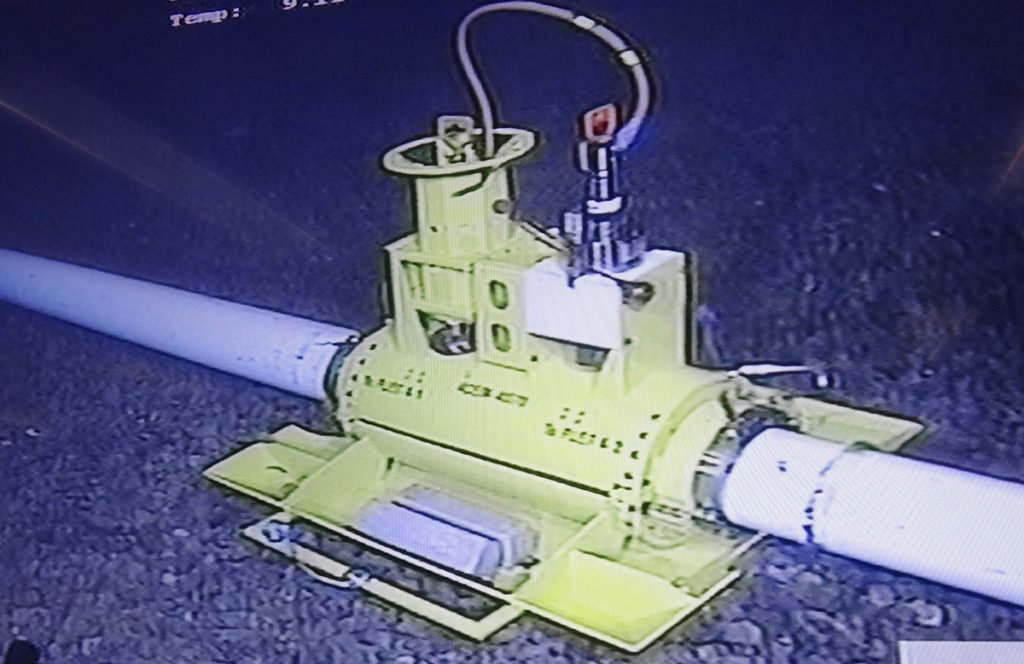

For the first time, ClampOn’s Corrosion-Erosion Monitor (CEM) has been installed topside aboard a pipe-laying vessel, and submerged as a fixed part of the pipeline.

Subsea installations of the CEM are plentiful, but installation from a pipe-laying vessel required the instrument to allow for the bending and twisting of the pipeline during deployment. ClampOn’s clever rotating protective cover made this possible.

The complete unit was installed topside aboard the pipe-laying vessel during regular operation, and then lowered onto the seabed as part of the pipeline. It is now monitoring corrosion on a large gas export line in the North Sea, from where it provides the operator with continuous information of the pipeline wall thickness. As it is located far away from the shore, subsea trees, manifolds, or any other infrastructure, the system operates stand-alone, using battery as its energy source.

More articles

-

26.01.2026 | Company | Product

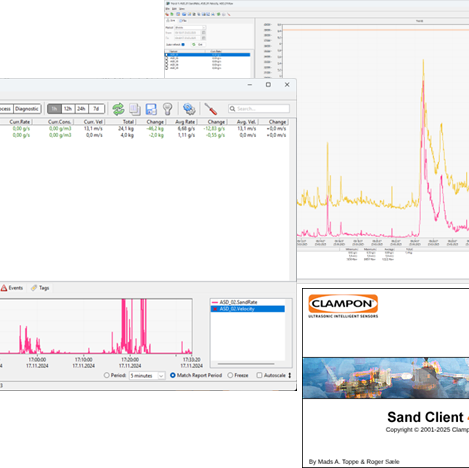

26.01.2026 | Company | ProductIntroducing ClampOn Sand Monitor 4.0

ClampOn Sand Monitor and Sand Client 4.0

Article by Mads Toppe -

09.01.2026 | Company | Product

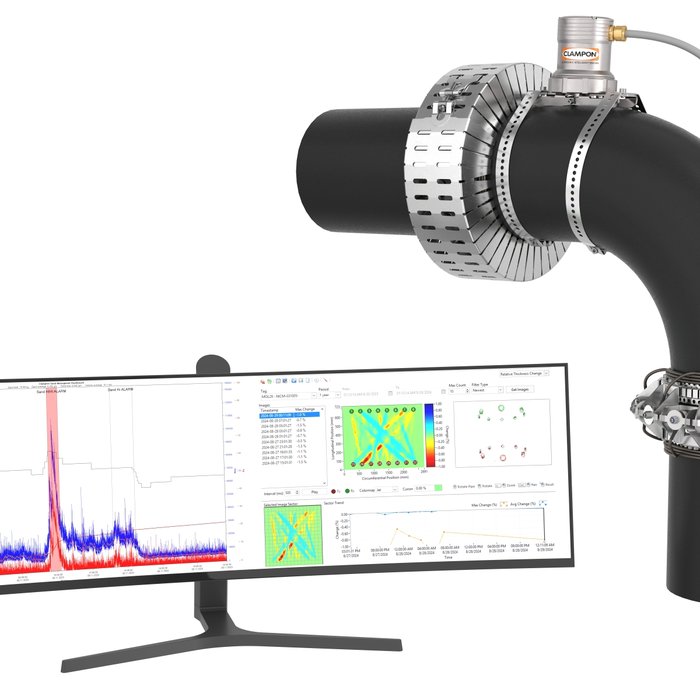

09.01.2026 | Company | ProductClampOn Sand & Erosion Monitoring - Not a Single Spot Missed

In a pipe bend, erosion does not play by the rules - it can strike anywhere, at any time.

Article by Eirik Walle -

22.12.2025 | Company | Product

22.12.2025 | Company | ProductPIG Signalling Ex i and Ex d e

The ClampOn PIG Detector provides precise pig monitoring using advanced acoustic and magnetic technology. Choose between Ex i and Ex d e for optimal safety in hazardous areas, without compromising performance.

Article by Tonje Dahl -

04.11.2025 | Company

04.11.2025 | CompanyExpanding our reach in the Middle East

Kristina Oshin has joined ClampOn as Sales Director for the Middle East, based in Dubai

Article by Tonje Dahl