When sand production puts restrictions on wells, precise sand monitoring is key.

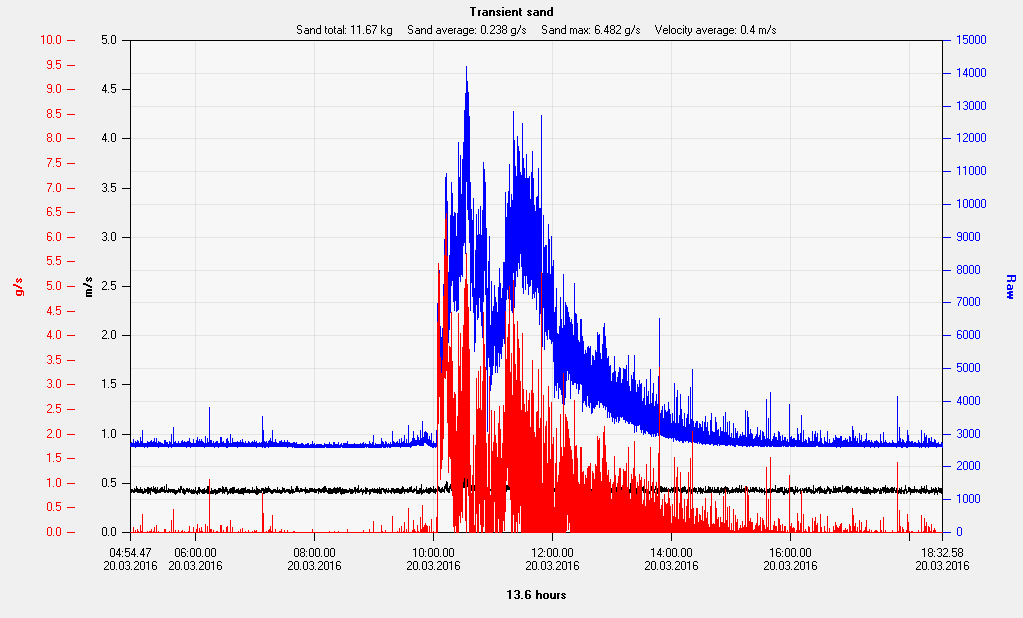

"We performed a well test for a client to find the highest rate of production while still keeping sand levels below a set amount. As a result, our client could increase their production rate and made millions extra," says Åsmund Bakke, ClampOn's Support Service Manager.

Bakke is in charge of ClampOn's Support Department. The department consists of support engineers with very different backgrounds and skillsets, including a member of the Norwegian cyber defence, a former Norwegian top cyclist, and a superb skier. Their common denominator is their experience with ClampOn's products. Most started as service engineers and travelled the world doing installations, commissioning, and well testing.

Their competence helps clients get the most out of their ClampOn equipment. While some clients ask for assistance in training their own personnel in how to interpret the data as accurately as possible, some choose to have ClampOn handle data interpretation completely.

"Those with high levels of sand production, or high velocity flows in combination with a potential for sand, benefit tremendously from support. Monitoring sand is not as easy as monitoring pressure and temperature, because a well's flow regime and the acoustics of the pipe are not constant. Precise measurements require time, human resources, experience, and continuity – which is what we offer. We have extensive knowledge of optimisation," says Bakke.

Each support contract is unique, tailored to the needs of the client. The department creates custom-made software, runs tests, assists the service department, and works closely with R&D at ClampOn who constantly looks for ways to improve the products.

"We strive to be the best at sand monitoring. If a client has sand production, they can rely on our instruments and measurements so that they can focus on running the well," says Bakke.

Sand monitoring is important not only for profitability, but also for safety. "If not controlled, sand can compromise wells, fill up pipes, damage reservoirs, cause unnecessary wear on equipment, cause erosion, and there could be serious incidents. We have the capability to run round the clock monitoring of high-risk well operations, and often send service engineers out in the field for on-site monitoring if we do not have remote access to data."

Quite frequently, the service department gets phone calls from clients asking for special assistance. Recently, a client called in reporting sand production on a specific well, and asked whether they should reduce production or just keep going while hoping for it to pass. "We were able to log on remotely through our server/client software and had a look. It turned out that the gas/liquid ratio for the well had changed, and the zero configuration for sensor was therefore now incorrect. We updated the system with the correct zero values and with the new values, the sensor showed that the sand values were still acceptable. Without us, the client would have reduced the production rate and lost a lot of money."

Customer testimonials

What some of our clients say:

- "Thanks to ClampOn Support, we've got a sand monitoring system we can rely on, and we save a lot of time as we no longer need to check sand traps or update zero tables ourselves. We've also been able to increase production rates on some of our wells, as the system had the wrong zero configuration before. Increased production is good for earnings," says Kari, production engineer.

- "After entering into a support contract with ClampOn, we haven't damaged a single choke. This demonstrates the importance of having a complete picture of sand production," says Chriss, production engineer.

More articles

-

Global agents gathered in Bergen

A week of learning, connection, and adventure

-

Subsea Sand and Vibration Monitoring

The project department is bustling with activity as we approach the Easter holiday.

-

Celebrating excellence: Sebastian Skei's top grade in vocational exam

Sebastian Skei achieved an 'Excellent' grade in his six-day vocational exam in Production Electronics

-

Corrosion Monitoring for project in South America

ClampOn have received a large contract for the supply of Subsea Corrosion Erosion Monitoring instruments for a project in South America.